1××× Series

It is industrial pure aluminum, and it is a brand series with the highest aluminum content. The aluminum content is not less than 99.00%. It has good elongation, tensile strength, plasticity and corrosion resistance. The production process is relatively simple, the production technology is relatively mature, and the price has a huge advantage, but the strength is low and it is easy to be deformed by compression.

Mainly used for signs, billboards, wall decoration, kitchen utensils, chemical equipment, electronic devices and other products that do not require high strength. It is a series commonly used in conventional industries.

At present, the 1100, 1050 and 1060 series of aluminum plates are widely used in the building decoration industry.

2××× Series

It is an aluminum-copper alloy aluminum plate (Al-Cu), with copper as the main alloy element, its content is between 3-5%, has high hardness and good cutting performance, has a certain heat resistance, can be heat treated, The disadvantage is poor corrosion resistance.

It is mainly used in industries and products that require high strength and high temperature resistance, such as aircraft structures, missile components, spacecraft parts, and ship bodies.

3××× Series

It is an aluminum-manganese alloy aluminum plate (Al-Mn), also known as an anti-rust aluminum plate, with manganese as the main alloying element, its content is between 1.0-1.5%, and its strength is higher than that of the 1-series aluminum plate.

It has good formability, weldability and corrosion resistance.

It is mainly used in industries with high requirements for anti-corrosion and anti-rust, such as building decoration industry, electronic manufacturing industry, and automobile manufacturing industry.

At present, 3003, 3004 and other series of aluminum plates are widely used in the building decoration industry.

4××× Series

It is an aluminum-silicon alloy aluminum plate (Al-Si), with silicon as the main alloying element, and its content is usually between 4.5-6.0%.

It has the characteristics of high strength, low melting point, good corrosion resistance, good wear resistance and small thermal expansion coefficient, and is mainly used in welding materials.

5××× Series

It is an aluminum-magnesium alloy aluminum plate (Al-Mg), with magnesium as the main alloy element, and has good processing and forming properties, corrosion resistance, welding properties, etc.

It is widely used in conventional industries because of its low density and lighter weight than other series of aluminum sheets. It is also commonly used in ship structures, aircraft fuel tanks, automobile fuel tanks, etc.

At present, the 5052 series of aluminum plates are widely used in the building decoration industry.

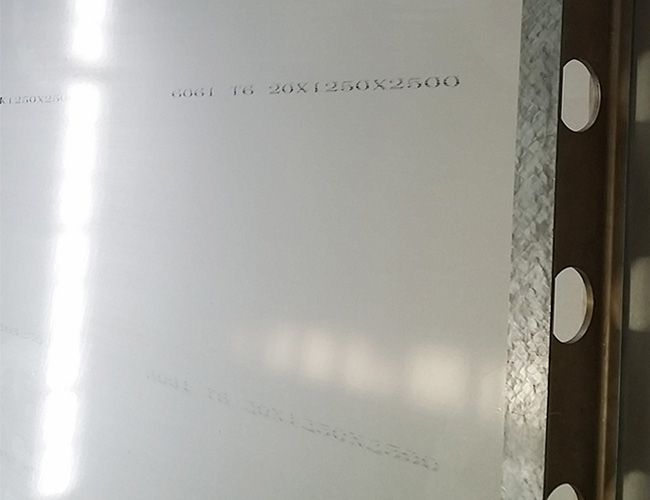

6××× Series

It is an aluminum-magnesium-silicon alloy aluminum plate (Al-Mg-Si), with magnesium and silicon as the main alloy elements, with medium strength, good corrosion resistance, good weldability and oxidation effect,

It is mainly used in industries and products with high requirements for corrosion resistance and oxidation resistance.

7××× Series

It is an aluminum-zinc alloy aluminum plate [Al-Zn-Mg-(Cu)], with zinc as the main alloying element, which belongs to superhard aluminum alloy.

It has good mechanical properties, wear resistance and fatigue resistance, but has poor corrosion resistance and needs to be covered with aluminum or other protective treatments.

Mainly used in aerospace equipment materials, but also widely used in various machinery, molds and other processing fields.

8××× Series

It belongs to other series of aluminum plates, with other alloys as the main alloying elements, most of which are used as aluminum foils, which can be used in bottle caps, radiators, etc., and belong to a less commonly used series.

< Introduction of decarburization lay... What are the production methods of... >