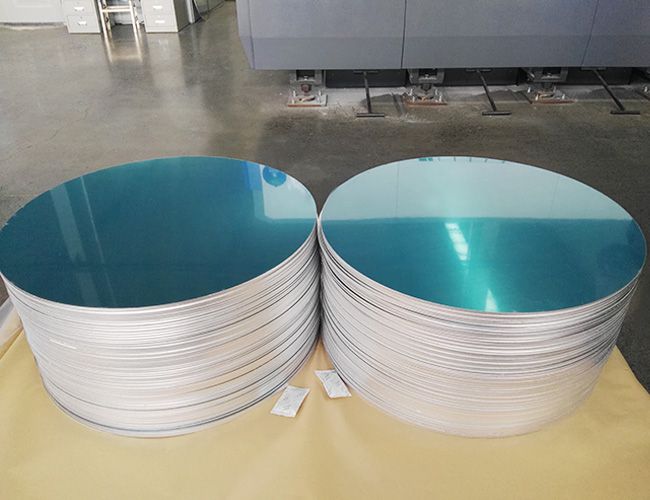

Aluminum wafer is widely used in electronics, daily chemicals, medicine, culture and education and auto parts. Electrical appliances, insulation, machinery manufacturing, automobile, aerospace, military, mold, construction, printing and other industries. Such as kitchenware products such as non-stick pans, pressure cookers, and hardware products such as lampshade, water heater shell, is one of the largest dosage of aluminum alloy sheet strip deep processing products.

Aluminum has good thermal and electrical conductivity, and the combination of good electrical conductivity and low density makes it a good long-distance transmission conductor.

There are some aluminum components in notebook computers and many electronic devices, which play an indispensable role, and the heat dissipation component is the use of aluminum's good thermal conductivity and low density.

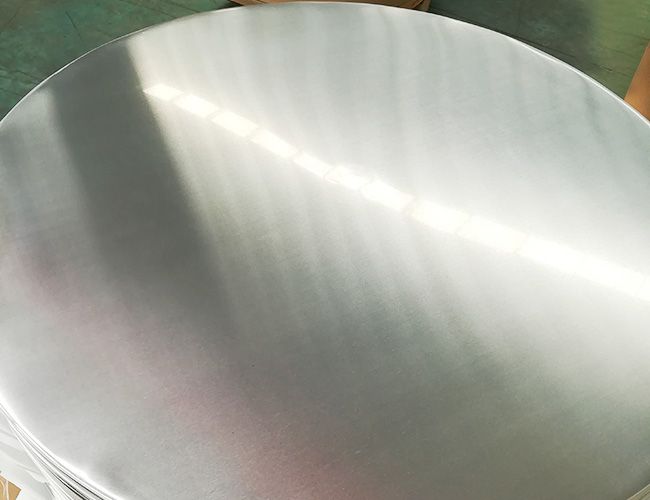

Super corrosion resistance. The surface of aluminum wafer and aluminum alloy has a layer of incomparable thinner than cicada wing alumina film, which is a layer of natural oxide film formed with oxygen in the air, the limit thickness of this film formed at room temperature is 2.5~ 3.0NM25 ~30A). This film is not only surprisingly thin, but also very dense, can not permeate oxygen, and aluminum wafer joint firmly, so that the aluminum wafer is no longer subjected to corrosion, that is, no oxidation, so that aluminum wafer and aluminum alloy after the service life, after treatment and remelting can get more than 95% of recycled aluminum.

Set clean, sanitary, beautiful and isolation in one. Aluminum wafer and aluminum alloy is a kind of silver metal, under ordinary atmospheric conditions, can always shine, white and flawless color, and non-toxic and tasteless. The cleanliness and hygiene of aluminum wafer makes it an excellent packaging material for food, beverage, medicine and wine, etc. It also has very good printable performance and can be printed on various patterns, colors and patterns.

Energy saving and recyclability is the strongest. Because aluminum wafer, aluminum alloy has very strong corrosion resistance, aluminum wafer under normal atmospheric conditions without maintenance, even if used for decades or even hundreds of years is still intact not corrosion, such as doors and Windows, such as Bridges, scrap regeneration after processing and smelting can obtain more than 95% of the recycled aluminium, higher than any other engineering materials, from sigh than even stainless steel, Because stainless steel in the use of the process, although not corrosion, but waste stainless steel in the process of melting regeneration burn than aluminum much larger.

< Overview of aluminum foil Industry Beautiful and practical pattern alu... >