Anti-rust aluminum sheet

Anti-rust aluminum plate seems to have become a much favored product. 3003 aluminum plate is the most common product in the aluminum-manganese alloys. The 3003 aluminum plate has a manganese content of about 1.2-1.5%. Therefore, the 3003 aluminum plate is harder than the 1 series aluminum plate in hardness. For example, for the comparison of 3003 aluminum plate and 1060 aluminum plate, the general hardness of 3003 aluminum plate is about 10% higher than that of conventional 1060 aluminum plate.

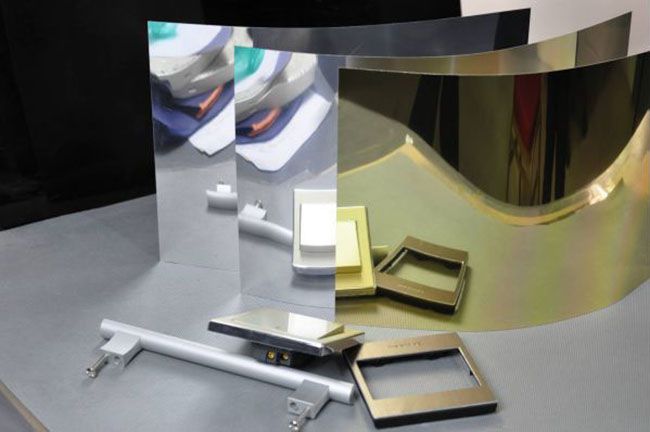

Mirror finish aluminum sheet

It is refers to the aluminum plate that is processed by rolling, grinding and other methods to make the surface of the plate show a mirror effect. The reflectivity is as high as 86% or more, and the color effect is good. It is widely used in lighting reflection, decoration, hardware signs and other industries.

According to your own product needs, you can choose polished aluminum sheets with different colors. It has two kinds of packaging: aluminum plate and aluminum coil.

Marine grade aluminum sheet

It mainly include Al-Cu, Al-Mg and Al-Si series aluminum alloys. Most aluminum alloys exhibit excellent corrosion resistance in marine environments. This is not only due to the action of the protective passivation film, but also to a considerable extent related to the high overpotential for hydrogen evolution on the activated and passivated surfaces of Al.

As a marine aluminum plate, 5083 aluminum plate has a very high applicability in the marine industry. In addition to the processability of 5083 aluminum plate, the most important thing is the weldability and corrosion resistance of 5083 aluminum plate.

< Causes of Surface Scratches on Mari... What raw materials are aluminum foi... >