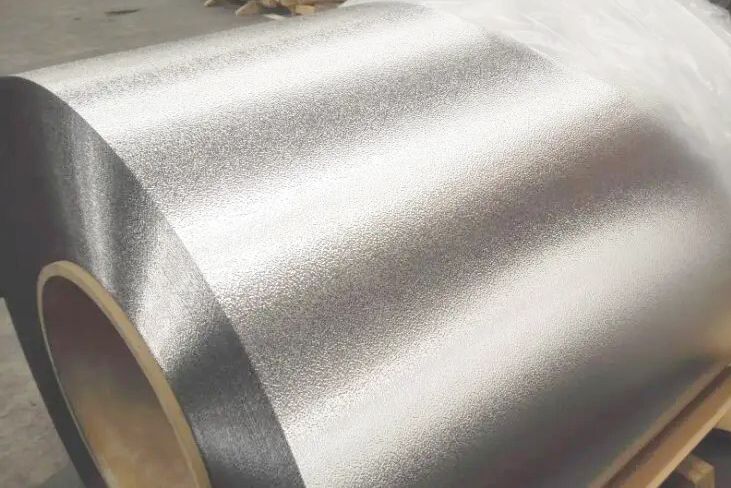

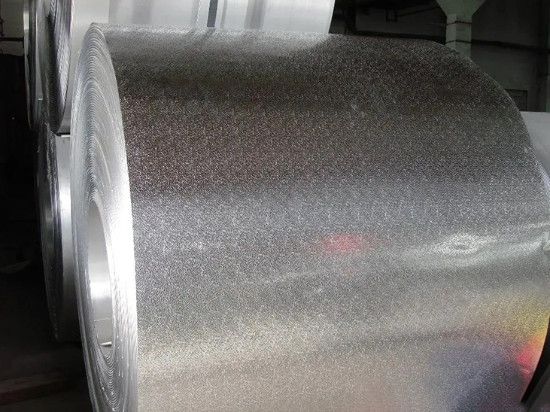

Orange peel aluminum coil is made by placing aluminum coil in corresponding electrolyte and electrolyzing under specific conditions and applied current. A thin layer of aluminum oxide is formed on the surface of orange peel aluminum coil, with a thickness of 20 microns and a hard anodic oxide film of up to microns. Orange peel aluminum coil The orange peel aluminum coil improves its hardness and wear resistance, and has good heat resistance. The melting point of hard oxide film is very high. Orange peel aluminum coil has excellent insulation, breakdown voltage resistance and enhanced corrosion resistance, and will not corrode in salt fog for thousands of hours.

There are a lot of micropores in the thin oxide film, which can absorb various lubricating oils, and is suitable for manufacturing engine cylinders or other wear-resistant parts; The film has strong microporous adsorption capacity and can be dyed into various beautiful colors. Nonferrous metals or their alloys can be oxidized. Orange peel aluminum coil is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, architectural decoration, machine shell, lamps and lighting, consumer electronics, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries. Orange peel aluminum coil has the advantages of good processability, strong decoration, moderate hardness, easy bending and forming, continuous high-speed stamping, and convenient direct processing into products.

Orange peel aluminum coil has good weather resistance and will not change color, corrode, oxidize or rust when used indoors for a long time. Strong sense of metal, high surface hardness, good scratch resistance, no paint cover on the surface, and the metal color of aluminum coil is retained. High fire resistance, no toxic gas generated, meeting the requirements of fire protection and environmental protection. Strong dirt resistance, easy to clean, no corrosion spots. It has strong applicability and wide use, and is suitable for metal aluminum ceiling, fireproof board, electrical board, cabinet board, furniture board, etc. In short, it is very practical.

< Aluminum foil for flexible packing What is the difference between pure... >