Roll coating on the surface of aluminum plate is a metal processing technology. It has the advantages of good environmental protection and persistent interpretation. Compared with the roll-coated aluminum plate, the roll-coated aluminum plate has a higher melting point, the general temperature can't reach its melting point, and it has good adhesion, acid resistance and corrosion resistance. Compared with the coated aluminum plate, it reflects light softly and is easy to clean, but the price is also a little higher than that of the coated aluminum plate. Next, I will share with you the roll coating process of aluminum plate surface.

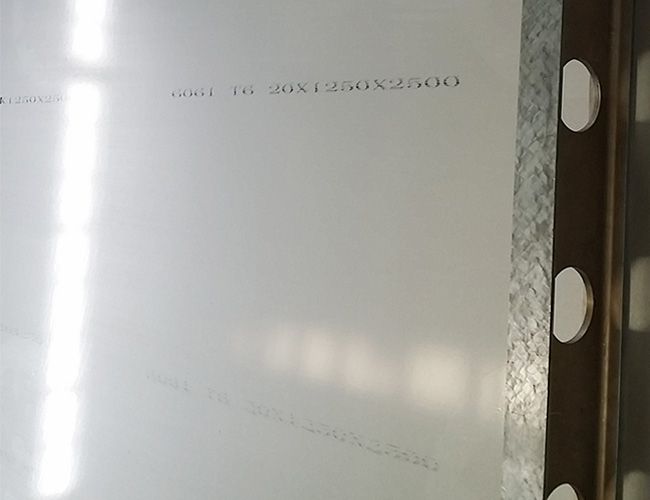

After degreasing and chemical treatment on the surface of aluminum plate, roll coating a better coating, drying and curing. The flatness of paint film on the surface of rolling plate is higher than that of spraying plate. The color is divided into pearlescent and matte, and pearlescent is common in the market. Its price is higher than that of spraying. The bigger feature of the roller plate is that the color simulation degree is extremely high; The quality and grade of roll coating process vary greatly. Apart from all materials, there is also something to do with its coloring in several times. For example, two coats and two rolls, that is, spraying once and baking once, and then spraying and baking again, make the color more uniform and smooth. Good roll coating board is also very expensive, with vivid color and strong durability.

Fluorocarbon roller coating is also a kind of roller coating, that is, fluorocarbon is added to pigment, which makes color adhesion stronger, service life longer, acid, alkali and corrosion resistance. It is often used for exterior decoration of buildings (not afraid of wind and rain), and its price cost is very high, so it is a better roller coating.

The surface treatment process of aluminum roll coating is as follows:

Roller coated aluminum plate has topcoat, primer and backcoat. The backcoat mainly plays an anti-oxidation effect and makes it last longer. Semi-finished products - upper machine - forming - lower parts and inspection - packaging and storage.

The surface of rolled aluminum plate is uniform and smooth, and there are no obvious defects such as coating leakage, shrinkage cavity, scratch and shedding. However, there are some defects such as bubbles, pits and inclusions on the surface, which are normal phenomena.

< What pretreatment sections are requ... Six unique processes of surface tre... >