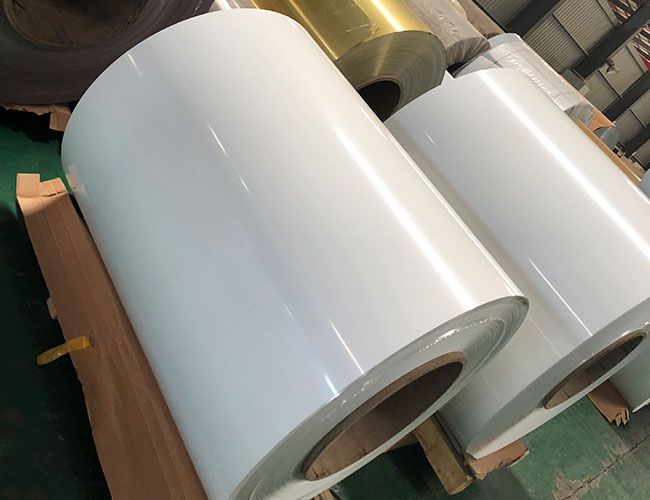

The so-called color coated aluminum coil, refers to the surface of aluminum alloy coloring treatment, because the performance of aluminum alloy is very stable, not easy to be corroded, the general surface after special treatment can ensure at least 30 years of color. More because of its density is small, hardness is high, the weight of unit volume is the lightest in metal materials, and the color is changeable, and will not always face plastic steel is always questioned "toxic" two words. So in the high-grade real estate doors and Windows, sun room, balcony packaging and other fields are widely used. Now, color coated aluminum rolls have become one of the most popular top decorative materials. It is a green product with environmental protection, durability and aesthetic characteristics. As a decoration material, it has the following incomparable advantages: uniform color, bright and clean, strong adhesion, durable, acid and alkali resistance, corrosion resistance, weathering resistance, decay resistance, friction resistance, ultraviolet radiation resistance, weather resistance.

Coating category: polyester coated aluminum coil (PE), fluorocarbon coated aluminum coil (PVDF).

Color coated aluminum coil product characteristics:

Flatness: no compound high temperature indentation on the surface. No residual stress, no deformation after shearing.

Mechanical: Select high quality aluminum, plastic and adhesive, adopt advanced composite technology. The product has the flexural and flexural strength required by the decorative plate. Under the climate condition of four seasons, the change of wind pressure, temperature, humidity and other factors will not cause bending, deformation, expansion and so on.

Environmental protection: resistance to salt, alkali and acid rain corrosion, its own corrosion will not produce toxic bacteria, does not release any toxic gas, does not cause keel and fixed parts rust, flame retardant. Not less than B1 level according to national regulations.

Hardness: The tensile strength of 1060 aluminum plate is between 110 and 130, and the tensile strength of 5052 series is between 210 and 230, that is to say, the hardness of 5052 is 100% higher than that of 1060.

Elongation: the elongation of 1060 series is 5%, while the elongation of 5052 series is between 12-20%. It can also be considered that the elongation of 5052 series is increased by about 200% when it is 100% harder than 1060.

Chemical properties: 1060 is pure aluminum plate, 5052 is alloy aluminum plate, 5052 corrosion resistance is better under special circumstances.

< The advantages of 1060 aluminum coi... Application of patterned aluminum p... >