Application fields of aluminum wafers

1. Aluminum discs have a low density and light weight, making them widely used in transportation manufacturing industries such as aviation, automobiles, and ships. In addition, high-tech industries such as spacecraft and artificial satellites also use a large amount of aluminum discs, aluminum metals, and aluminum alloys.

2. Although the conductivity of aluminum wafers is weaker than that of gold, silver, and copper, due to their large storage capacity and low density, which is only one-third of copper, the mass of aluminum that transports the same amount of electricity is only half that of copper. In addition, the surface oxide film of aluminum not only has the ability to resist corrosion but also has a certain degree of insulation, so aluminum circular metal has a very wide range of applications in the electrical manufacturing industry, wire and cable, and radio industry.

3. Aluminum discs and aluminum alloys are often used as forgings in industry, capable of casting various shapes and varieties of forgings, and can be connected using various methods, including fusion welding, resistance welding, and other welding methods. Mechanical methods such as bonding, riveting, and bolting can also be used for connection. In addition, aluminothermic agents are often used to melt refractory metals and weld steel rails, and can also be used as deoxidizers in the steelmaking process.

Aluminum wafer processing.

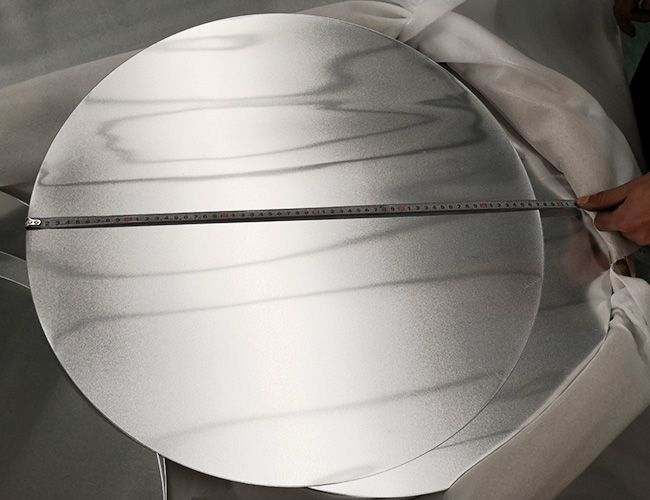

Aluminum wafers are made from aluminum alloy sheets as the main raw material, and are processed and packaged through a series of processes to obtain household and industrial products. So what are the main processing methods for aluminum wafers?

The main processing methods for aluminum circular plates are rolling, extrusion, drawing, and forging. In the deep processing of aluminum wafers, it is necessary to ensure the accuracy of the machine tool. The higher the accuracy, the better. The machine tool generally uses a static bearing spindle. The tools used must be diamond shaped solid tools, professionally polished.

Then, apply cutting fluid to it, which can be directly treated with a mirror surface to use emulsion. One of the processing techniques for aluminum wafers is heat treatment, known as finished product heat treatment. This treatment includes finished product annealing, solid solution treatment, quenching, natural aging, and artificial aging treatment. Artificial aging treatment can provide the mechanical properties of aluminum discs, improve their stress corrosion resistance and fracture toughness.

< Description of aluminum wafer proce... The application of curtain wall alu... >