For parts such as car doors, car hoods, and car front and rear fenders, the mature products we have developed are 5182 alloy sheets. Kk Aluminum's 5182 alloy aluminum plate has a good punching effect. From the customer's response, there is no cracking phenomenon after the aluminum plate is punched.

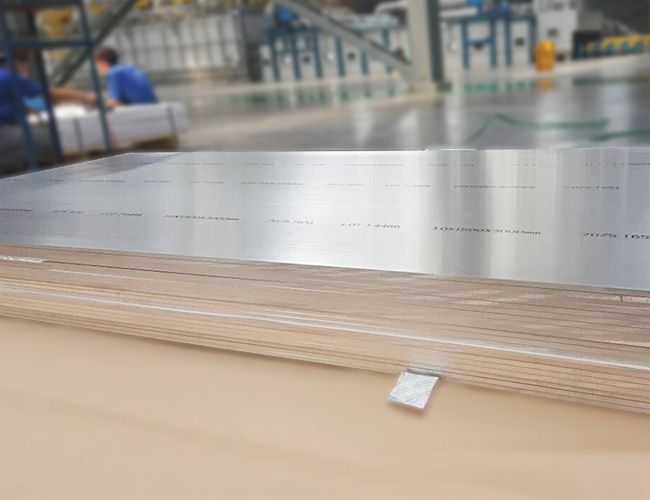

5182 aluminum alloy, the thickness range that kk can produce at present is 0.15-600mm, and the width range is 20-2600mm (cut according to customer needs).

The range of auto parts is relatively wide. The lightweight aluminum alloy products developed by kk aluminum for automobile bottom guards and automobile air tanks include 5083, 5754, and 5052 alloy aluminum plates. 5083 aluminum plate and 5052 aluminum alloy are the most widely used in these auto parts, the practical application effect is very good, and the market response is very good. kk Aluminum is currently mass-producing for customers.

The popularity of new energy vehicles and electric vehicles has forced changes in raw materials for automotive power batteries. kk has successfully developed products used in power batteries, mainly including 3003 aluminum strips for power battery shells, 1235 aluminum foils and 1060/1070/1100 aluminum foils for battery cells.

For 3003 aluminum alloy, the thickness range we can produce is: 0.20-4.5mm, and the width range: 20-2600mm. 1070 aluminum foil, 1235 battery foil, the market demand materials are generally H18 state, the thickness is generally 0.012-0.02mm, and the width range: 280-1200mm.

The thick aluminum plate for automobile wheels is mainly 6061 aluminum alloy. 6061 aluminum alloy is a heavyweight product developed by kk aluminum industry, and we have very mature technology. Thickness range that can be produced and processed: 0.30-600 Width range: 150-2600.

kk Aluminum has invested a lot of energy in automotive lightweight application materials, and has developed aluminum sheet, strip and foil products suitable for each component.

< What are the production methods of... Tips for choosing aluminum foil for... >