In the power battery system of new energy vehicles, the battery shell accounts for approximately 20-30% of the total weight of the system and is the main structural component of the battery. At present, many new energy vehicle battery cases use aluminum alloy frames and aluminum plate structures to reduce vehicle weight. The main reason is that aluminum alloy frames and aluminum plate structures can make the battery case structure design flexible, the process is more mature, and the weight reduction is significant. They can provide high stiffness and strength, and the aluminum plate stamping parts have good sealing performance.

The aluminum shell products of automotive power batteries mainly use 3003 aluminum plates, which have easy processing and forming, high temperature corrosion resistance, good heat transfer and conductivity. The aluminum shell of the 3003 aluminum alloy power battery (except for the shell cover) can be stretched and formed in one go, which eliminates the welding process at the bottom of the box compared to the stainless steel shell.

The use of 3003 aluminum alloy for packaging is very important in the production process of power batteries, as good packaging technology determines the safety and lifespan of power batteries.

The main alloy element of 3003 aluminum plate is manganese, with low density and soft material, which has the advantages of easy overall stretching and forming of power battery aluminum shell. The density of aluminum alloy is much smaller than traditional stainless steel packaging materials, which can achieve the lightweight development of automobiles.

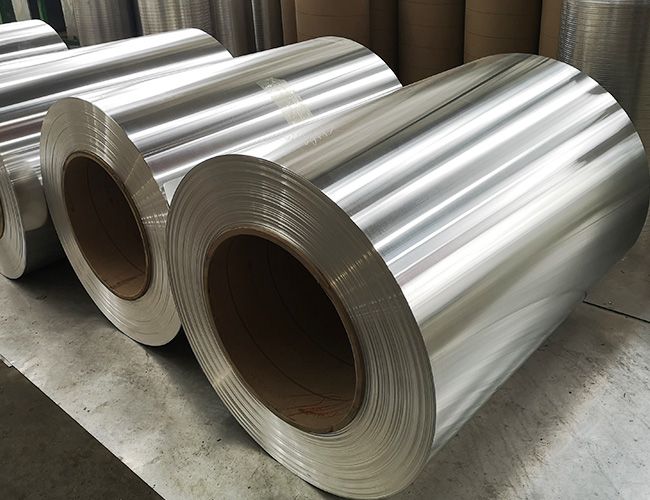

Power battery shell material 3003-H14 aluminum plate

Currently, the development of aluminum plates for 3003 power battery shells is undergoing a transition from a "0 state" to an "H14" state. The fundamental reason lies in the progress of technology. As a traditional manual punching state, the "O state" material has the characteristics of low production efficiency and yield. The material in the "H14" state is more suitable for automatic and semi-automatic punching, and has higher production efficiency.

< Aluminum sheet coils for ships and... Aluminum plate for battery tray >