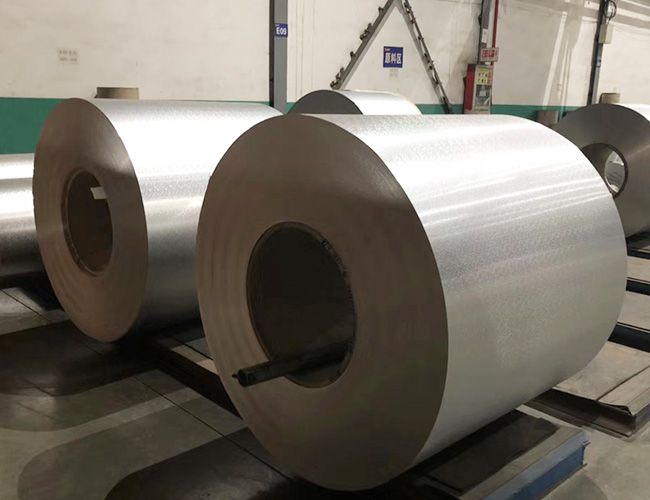

The current popular decorative aluminum plate with its popular durability, decoration, beauty and many other excellent characteristics are widely popular, but in the design and manufacturing process will inevitably appear some color difference problems. In order to effectively solve this thorny problem, here, we specially invite engineers from well-known pattern aluminum plate manufacturers in the industry to briefly explain four effective and practical solutions and skills to solve the pattern aluminum plate dyeing problem.

First, choose raw materials from aluminum plate parts anodic oxidation has the best coloring function of aluminum, aluminum magnesium, aluminum manganese alloy, and can color different colors, for heavy silicon plate or copper plate in the dyeing process can only consider reasonable black and dark.

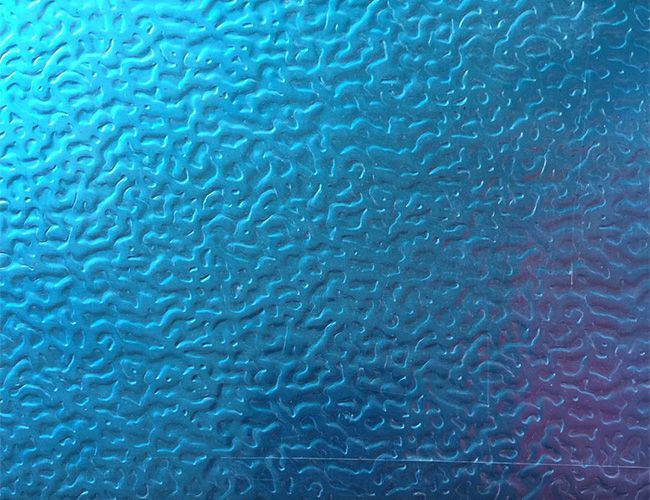

Two, be sure to do a good job of the oxide film thickness. The thickness of oxide layer should also be controlled. The thickness of glass and aluminum plate can be controlled above 10um, and the porosity and light transmittance can achieve ideal color effect.

Three, the concentration of dye solution it is the developer concentration and developer concentration has a strong correlation. When the aluminum plate is colored in light, the concentration may decrease, and in the dark the concentration may decrease if the color concentration is high, the color is not uniform or liquid, easy to clean and seal. In order to better improve the adsorption capacity of the dye, the use of low concentration of dye for a longer time of basic coloring, so that the dye molecules can more evenly permeate into the deep hole of the oxide film, can make the dye color more natural, but also can do relatively more firm.

Four, the temperature control of the dye solution needs to be controlled well. Control color aluminum plate coloring problem, usually divided into cold color and hot coloring. That aluminum plate manufacturer uses long cold dye in the production process, so they are not for the color interest expiration hot coloring time is relatively short, it is difficult to solve the coloring problem. If it is found that the temperature is too high, it will reduce the adsorption of dye, leading to the phenomenon of dizziness on the surface of the aluminum plate.

< What is aluminium coil? What are th... Aluminium sheet for easy pull cover >