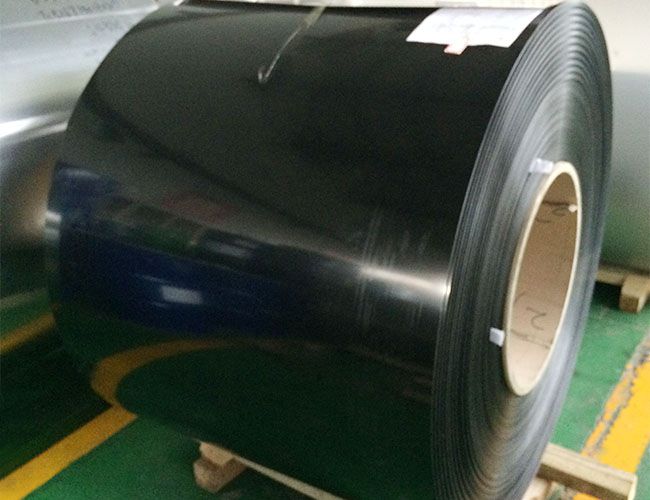

Color coated aluminum coil refers to the surface coating and coloring treatment of aluminum coil, which has very stable performance and is not easily corroded. After special treatment, the surface can achieve a 30 year quality guarantee, and the weight per unit volume is the lightest among metal materials. Color coated aluminum coil is currently the most popular new type of material.

Below are several major characteristics of color coated aluminum plates.

1、 Flatness:

No composite high-temperature indentation on the surface. The board surface has no residual stress and does not deform after shearing.

2、 Decorative:

Painted with wood and stone patterns, it has a realistic physical texture and a lively natural beauty. The pattern is made at will, giving customers a wide range of personality choices, which can enrich the humanistic connotation of the product and give people more enjoyment of beauty.

3、 Weathering resistance:

The paint pattern formed by coating and high-temperature baking has high gloss retention, good color stability, and minimal color difference changes. Polyester paint has a warranty of 10 years, while fluorocarbon paint has a warranty of over 20 years.

4、 Mechanical:

Select high-quality aluminum, plastic, and adhesive, and adopt advanced composite technology. The product has the bending and bending strength required for decorative panels, and under four seasons of climate conditions, changes in wind pressure, temperature, humidity and other factors will not cause bending, deformation, expansion, etc.

5、 Environmental friendliness:

It is resistant to salt alkali acid rain corrosion, does not corrode or produce toxic bacteria, does not release any toxic gases, does not cause corrosion of keels and fixed parts, and has flame retardancy. According to national regulations, it shall not be lower than B1 level.

Colored aluminum rolls have a rich range of colors, which can add color to residential buildings, large commercial outlets, and large exhibition centers. Good plasticity and mechanical processing properties make it an ideal material for various architectural shapes.

< What are the commonly used automoti... Analysis of Performance Requirement... >