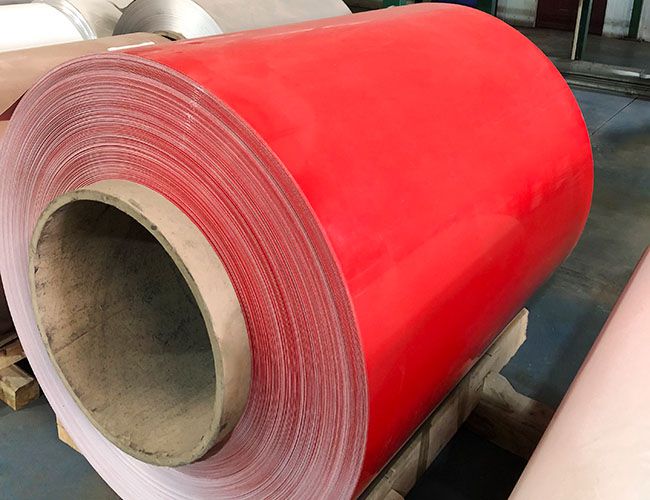

Color coated aluminum coil processing process

1, cleaning and pretreatment

This method is more efficient than traditional methods after repeatedly cleaning the pretreated aluminum coil with water jets, and the water can be reused, thus reducing power consumption. It can improve the anti-corrosion performance analysis of enterprise products and improve the adhesion of coatings. In this stage, through the formation of a chemical conversion film on the surface of the aluminum method, effective technology to improve product quality and reduce waste.

2. Coil coating

Coating process is mainly divided into two stages, respectively called bottom coating and surface coating. In one stage, the aluminium coil passes through a roller coating machine and is primed on one or both sides. After drying, the aluminum coil passes through two roller coating machines, at this time, the aluminum coil is coated with paint on one or both sides.

3, curing, subsequent processing

The aluminum strip passes through a curing furnace and is set at a regulated temperature to ensure that volatiles are removed from the strip and that the paint is completely cured. Depending on the needs of the coating system, the curing temperature is set between 200 and 300 degrees Celsius, which is a key technical point to ensure the quality of the product.

< What is colored aluminum coil? Color coated aluminum coil product... >