Color coated aluminum roll

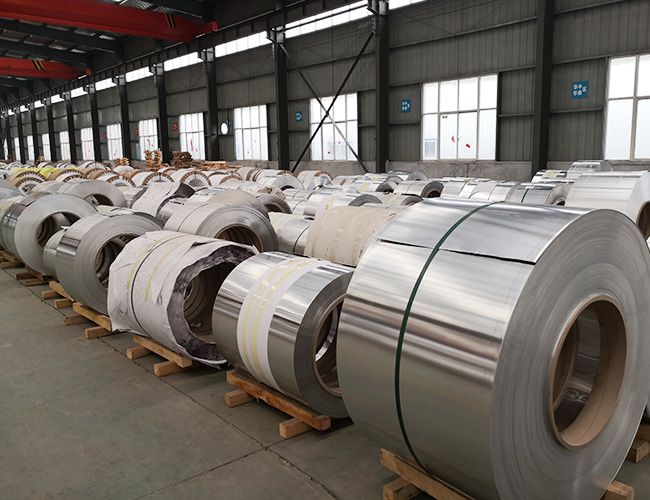

After cleaning, chromizing, roller coating, baking paint, and other treatments, the surface of the aluminum coil is coated with various colors of paint, that is, colored aluminum coil.

Colored aluminum panels are widely used in aluminum plastic panels, honeycomb panels, insulation panels, aluminum curtain walls, louvers, rolling shutters, aluminum magnesium manganese roofing systems, aluminum ceilings, household appliances, water pipelines, aluminum cans, and other fields due to their advantages of light weight, bright color, convenient processing and molding, and non rusting.

Coated aluminum coils can be simply divided into polyester (PE) coated aluminum coils and fluorocarbon (PVDF) coated aluminum coils based on different types of surface coatings. This is certain. This is the case where one side is coated with fluorocarbon, the other side is coated with polyester, and even both sides are coated with fluorocarbon.

Aluminum rolls, also known as embossed aluminum rolls, have various patterns such as orange peel and diamond patterns.

Due to their different uses, they are often referred to as roof materials (aluminum magnesium manganese structural roofs), ceiling materials (aluminum alloy ceilings), home appliance boards (used for decorating internal appliances), food materials (food grade chrome and roller coating), wire drawing boards (surfaces treated with wire drawing), and so on.

Aluminum plastic composite plate, abbreviated as aluminum plastic plate, is a composite material made of aluminum plate as the surface, treated and coated with paint, and polyethylene plastic plate as the core layer through a series of processes.

Aluminum corrugated composite plate is an all aluminum alloy composite plate formed by vacuum bonding of aluminum alloy panels, bottom plates, and aluminum corrugated cores.

The inner and outer layers are aluminum honeycomb panels, and the middle interlayer is a hexagonal aluminum foil honeycomb core. The honeycomb core is composed of structural adhesive and aluminum alloy surface layer panels.

The outer wall metal insulation board surface is color coated aluminum plate. The aluminum plate can be decorated according to the design requirements. It mainly plays a decorative role. At the same time, it has good weather resistance, corrosion resistance and self-cleaning. The middle layer is hard polyurethane foam, with good thermal insulation performance.

< Processing Technology of Aluminum P... Introduction to the Application of... >